Compelled by high cost of commercial feed and low egg production, a group of farmers-turned-entrepreneurs began making nutritious chicken feed with locally available ingredients that cut input costs drastically, significantly increased egg production of Kuroiler poultry and subsequently, their profits.

Kuroiler chicken at Zaone Poultry Company Photo: Ken Gunsalu

Zaone Poultry Company in Thyolo and Chimtengo Youth Poultry company in Chiradzulu are two Small and Medium Enterprises (SMEs) established under the EU funded CLIM2 project in Malawi. In 2019, the project introduced to them Kuroiler chickens, a dual-purpose breed originally bred in India that was introduced in Malawi from Tanzania. This hybrid chicken is known to outperform local chicken breeds under free range, semi-intensive and intensive management systems.

“There is a huge demand for eggs and poultry meat. However, a large gap exists between demand and supply of affordable poultry products. This presented us an opportunity to tap,” Dorica Jailosi, the Chairperson of Zaone Poultry Company, said while explaining the rationale for taking to Kuroiler chicken.

Accounting for nearly 60 to 70% of input costs, chicken feed is an important aspect of profitability in the poultry business.

“Most people in our community did not believe that we would manage raising Kuroiler chickens considering high cost of commercial feeds,” narrates Monica Mapemba, Chairperson of Chimtengo Youth Poultry Company.

Photo: Sabine Homann Kee Tui, ICRISAT

Months after they began, the companies’ members began noticing a drop in egg production of Kuroiler birds. They suspected the expensive commercial feed they were giving the birds and realized that unlocking the profit potential of the prized chicken variety they had was only possible if the feed became cheaper without impacting nutrition. It was clear that the farmers had to prepare their own feed.

CLIM2 began building the capacity of these farmers to prepare their own scientifically-formulated feeds. The efforts to develop local feed have been so successful that the farmers no longer buy commercial feed. Instead, they are able to locally source all ingredients, including minerals, to prepare feed. The feed is made of maize, maize bran, soybean, pigeon peas, sorghum, salt, microbial crude protein (MCP), metabolizable energy (ME) and lime. Most ingredients are bought soon after harvest when farmers sell their fresh produce and prices are low.

“Milling the feed stuff was easy with the hammer mills the CLIM2 project provided,” added Ms Mapemba. Buying the feed when prices are low, low transport and labor cost for processing feed stuff made the feed much cheaper than commercial feed.

Meat of the matter

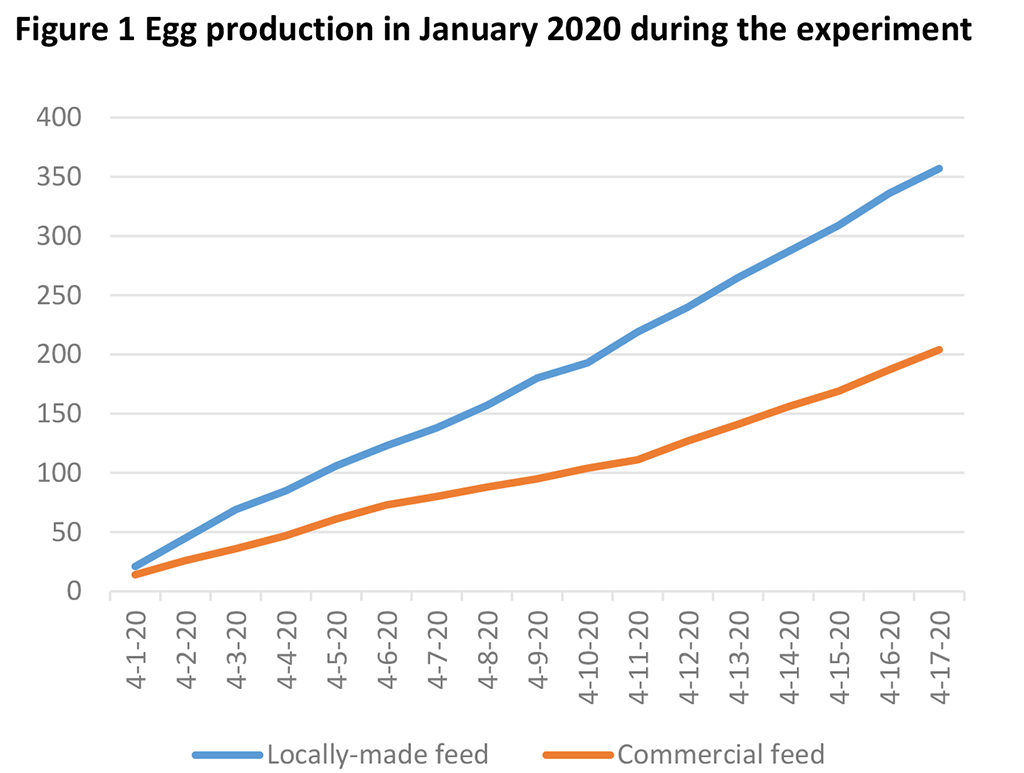

Low production of eggs and high cost of commercial feed triggered CLIM2 project to conduct feed trials with Zaone Poultry Company to compare feeds, egg production and the cost when birds are given commercial and locally-made feed.

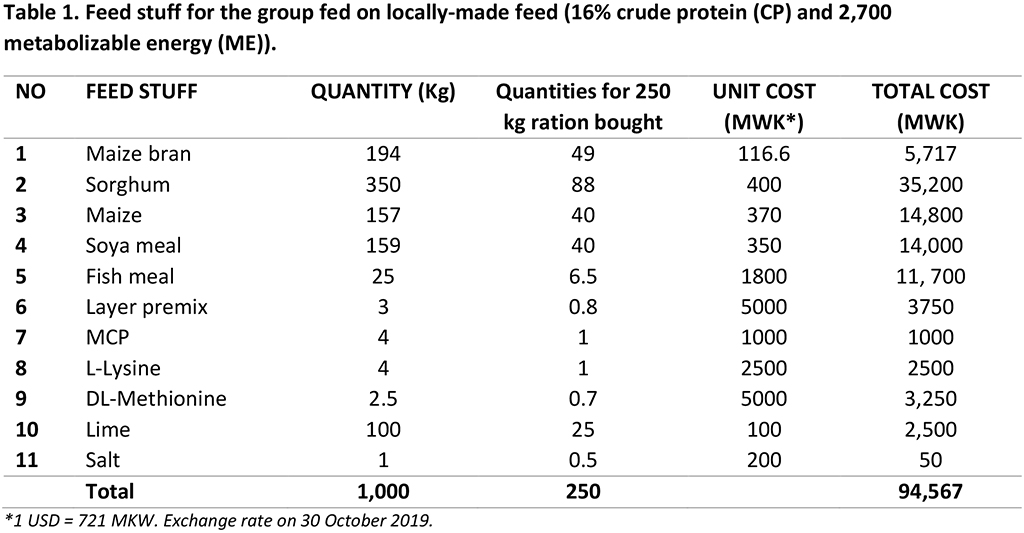

With the help of Donald Kaonga, a PhD student at ILRI, the company formulated its feed ratio using locally available feed stuff. They then conducted a simple study; 30 hens were fed locally-made feed and 30 were fed commercial feed. Each hen was given 120 g of feed per day. Data on egg performance under the two treatments was collected for 14 days. Table 1 lists the feed stuff for locally-made feed. Table 2 illustrates egg performance of the two groups.

Hens given the locally-made feed performed well with an average of 20 eggs per day (=67% laying). Hens fed commercial feed laid 9 eggs per day (30% laying). Apart from being more expensive, the commercial feed was also of lower quality.

“We are happy that we are now able to produce more number of large eggs using our own feed at a reduced cost. This will increase the company’s profit and it will improve our household income. It will also improve nutrition in our communities. It helps us in diversifying our business,” Mr Salima Phiri from Zaone Poultry Company beamingly said.

Feeding locally-prepared feeds can halve the feed costs for smallholder farmers. Following the experiment, the farmers learnt that a ton of locally-prepared grower feed with soy was costing 267,990 MWK while commercial feed was costing 492,000 MWK per ton.

The quality of locally–prepared feed is known to farmers and is high when they use the right quantities and types of feed stuff. High quality feed results in increased egg production when compared to commercially-produced feeds that are not under farmers’ control.

With increased egg production, poultry SMEs can find reliable markets beyond the communities in which their members live. The SMEs also become buyers of crop products that farmers within communities produce, thereby acting as a ready market.

Authors

Chamuka D. Thebulo, Donald A.M. Kaonga, Ken Gunsalu, Michael Blummel, Sabine Homann Kee Tui, Sikhalazo Dube

Add Comment