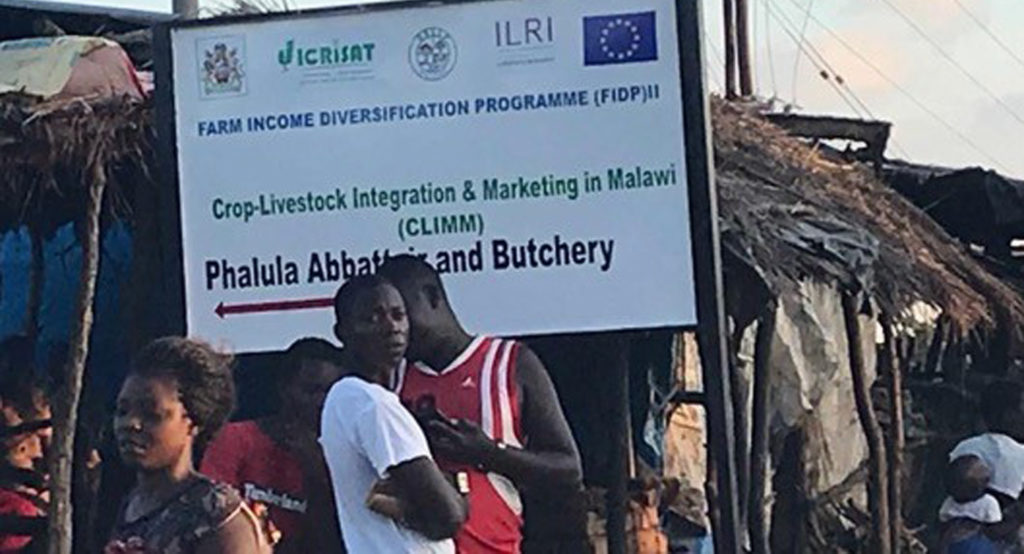

To Phalula’s goat butchery. Photo: Temwa Mwula

The meat trade in Malawai’s Phalula is on the cusp of transformation with butchers set to turn businessmen courtesy of a modernized slaughterhouse powered by a savvy business model.

The EU-funded CLIM2 project is using the Innovation Platform (IP) approach by engaging key players in livestock value chain including farmers and butchers, and municipal administration to transform the meat business. In a series of participatory meetings, the IP helped butchers set a vision for the trade and determined strategies for realizing it, which hinge on safe and high-quality meat fetching higher prices; inalienable to the vision would be creating hygienic conditions for goat slaughter and meat sales.

The need for change

Like most Micro Small and Medium Enterprises (MSMEs) in Malawi, butchers at Phalula, in the country’s Balaka district, work in a challenging environment which is sieged by weak self-organization, limited capital and marketing strategies. Emerging MSMEs often lack the capacity to kickstart and establish their operations.

The Balaka butchers say they are motivated to invest where business environment is conducive. They are aware of roadblocks to greater profits. In one of the meetings, they called for improved infrastructure and capacity building in business management and meat processing.

Installation of refrigeration container at the Phalula butchery. Photo: Temwa Mwula

“I would like to buy goats in bulk at a single point, process them into good quality meat to supply wider markets,” Timothy Chauluka, a young butcher, said while supporting the strategies at one of the meetings.

Modernizing Phalula’s meat trade

Livestock pens, prefabricated slaughter amenities and refrigeration containers are being put in place at the market. The sales-pens will boost farmer supply of goats while reducing aggregation costs. Butchers will spend less time visiting farms to source goats. The cooling facilities will extend meat shelf life, facilitate meat processing and value addition which can boost incomes.

Collaboration with various stakeholders helped in performing the modernization tasks. CLIM2 engaged with Balaka District Council for approval of market infrastructure and upgrading facilities. The council helped in drawing plans and site maps and initiated dialogue with the local market committee to allocate space for containers. Talks were also held for having an MOU to govern operations of the slaughter house.

Installation of refrigerationcontainer at Phalula abattoir Photo: Temwa Mwula

The District Agriculture Office provided land for the pen at Phalula EPA. “CLIM2 is a government project under FIDP II. Having a livestock pen at Phalula EPA will ensure sustainability of the establishment in terms of not only security of the facility, but also involvement of extension staff in supervising goat sales through animal inspection and weighing, setting prices and recording sales,” said Dennis Zingeni, the District Agriculture Development Officer, (DADO) while welcoming the idea of a pen.

During installation of refrigeration containers, Mr Wilson Kachere, Vice Chairperson representing the butchers’ group, exclaimed, “Now I can see that all strategies we set are connected. The cooler at the slaughter house can store meat from hundreds of goats and sales pens will improve collection of the animals.”

With one cooler at the slaughterhouse and another attached to the fabricated butchery, work is underway to install a three-phase powerline to run the coolers.

Doing business

To increase their chances of qualifying for loans and targeting high value markets, CLIM2 encouraged Phalula’s butchers to register as a company

The butchers were then trained in enterprise management. The company’s structure was also formulated. At the center of the structure formulation is the idea that butchers will migrate from doing everything to hiring personnel for managing different areas of their business. Each butcher will contribute shares to the company. The butchers will further be trained in meat handling and processing, business management and group dynamics to fulfill leadership roles and responsibilities.

In a meeting with the District Council, Prof Sikhalzo Dube, the project’s MSME Specialist, said, “We are using the slaughterhouse to attract supply of high quality goat from farmers. Meat grading, refrigeration and hygienic handling of meat is bound to increase sales. Construction of sales-pens will ensure butchers have a reliable supply of quality goats from farmers.”

An MOU has been put in place between the butchers’ company and Balaka District Council, which owns the slaughterhouse, to determine how much the butchers will pay for the infrastructure. The butchers’ company will receive seed capital from the project to cover infrastructure investment. They will contribute 10% from their resources.

Responses from local community

The community has welcomed the development as a step in the right direction, with many expressing keenness to purchase safe and hygienic meat from the improved slaughterhouse.

Challenges remain on changing the mindset of butchers to operate the business as a company. The consumers have to be made aware that the company will sell chilled and not frozen meat given that many feel the weight of frozen meat is misleading. Responding to fears of high electricity cost for running the coolers, Prof Dube assured the butchers that coolers are set to chill meat to a set temperature and automatically shut off, ensuring efficient power consumption.

About CLIM2

The project on Improved livelihoods through sustainable intensification and diversification of market- oriented crop-livestock systems in southern Malawi (CLIM2) is working to strengthen diversification and integration in crop-livestock farming systems in three districts of Malawi. The project is funded by the European Union under the Farm Income Diversification Programme (FIDP) Phase II – Agribusiness. The project is implemented by the International Crops Research Institute for the Semi-Arid Tropics (ICRISAT) as the lead agency, in collaboration with the International Livestock Research Institute (ILRI) and Small-Scale Livestock and Livelihoods Programme (SSLLP); and several departments within the Malawi Ministry of Agriculture, Irrigation and Water Development.

Project Team

Sikhalazo Dube (ILRI), Michael Blummel (ILRI), Siboniso Moyo (ILRI), Andre van Rooyen (ICRISAT), Sabine Homann-Kee Tui (ICRISAT), Sute Mwakasungula (SSLLP), Chamuka Thebulo (ICRISAT/ILRI).

About the author

Temwa Mwula,

Balaka District Coordinator, Small-Scale Livestock and Livelihoods Programme (SSLLP)

Add Comment